In this article, thepassionatewriter.com will try to examine the advantages of the busbar system.

Busbar System

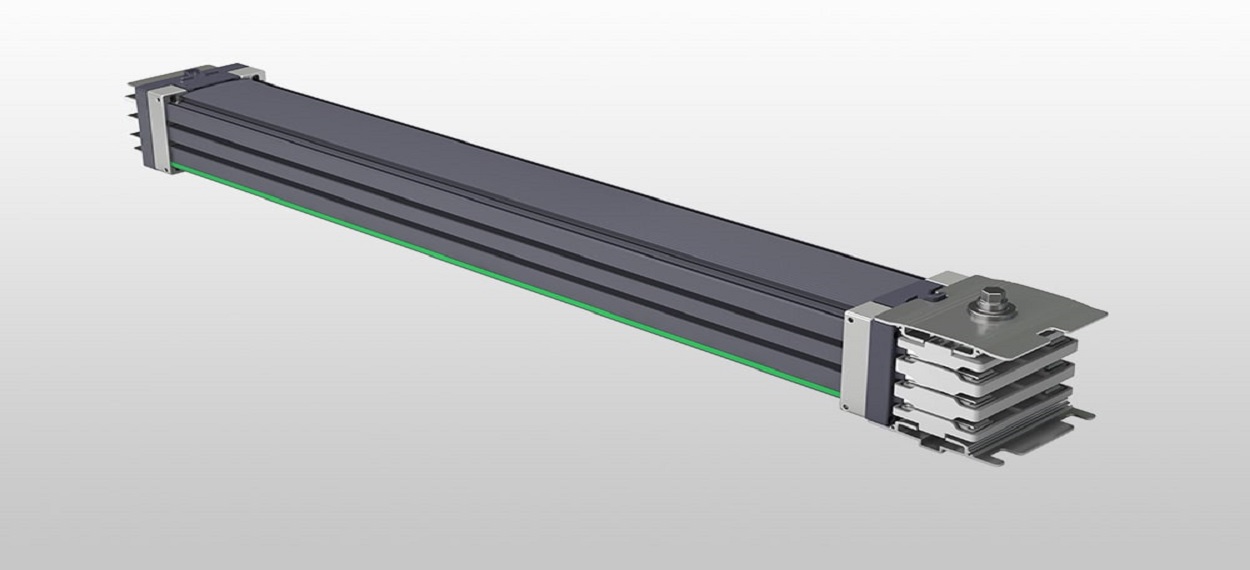

A busbar is a channel containing an aluminum or copper conductor (bar) within an aluminum or sheet metal casing that provides energy transmission and distribution.

The busbar system is an excellent alternative to wired systems in commercial and industrial applications.

Busbar systems are not as complex to configure as cable, are cheaper to install, and are easier to replace, especially in applications where load locations may change.

Where is The Busbar System Used?

Busbar system is often used to safely implement the distribution of three-phase power:

Busbar system is used in high-rise buildings, factories, workshops, assembly lines, warehouses, stations, hotels, airports, petrochemical plants, data centers, supermarkets, etc. that require medium and low voltage current distribution. Busbar channels are used in various application areas such as

Advantages of The Busbar System?

Busbar channel systems make electrical installation and distribution easier and more flexible than cables. Different coating materials used in production vary the lifespan and conductivity degree of the Busbar product.

1) Installation time is shorter than cable systems. This also saves money. The higher the current rating of the system to be installed, the greater the difference in workmanship between two different systems (Busbar-Cable systems).

2) Flexibility regarding project planning and future changes.

3) Enhanced safety achieved by using high-quality materials and components,

4) Environmentally friendly: The insulating materials used in busbar main line systems do not contain halogen, which means that toxic gases will not be released in case of fire. Additionally, the majority of the materials used are recyclable.

5) Aesthetics: Busbar channel systems are compact and their enclosures can be painted to be compatible with the environment.

6) Its mechanical and electrical resistance is higher than cable.

7) It does not require special care.

8) It has a longer life than cable.

9) It can be moved to another location.

Comparison of Busbar Systems with Copper and Aluminum Conductors

Aluminum busbars have both advantages and disadvantages compared to copper busbars. This makes them tailored to the customer’s needs.

Aluminum busbars are approximately 70% lighter than copper. This saves on labor costs due to easier installation and less support requirements and is much more competitive in price.

However, since its electrical conductivity depending on volume is lower than copper, aluminum busbars generally need to be larger to have the same conductivity.

Copper busbars are much more conductive than aluminum busbars. Therefore they tend to be more compact. However, copper has a higher unit price and also requires more support and therefore more labor costs due to its weight.

What Are The Busbar Types?

We can group busbar systems under 3 main headings. Power busbar systems, lighting busbar systems and trolley busbar systems.

Power Busbar System: Manufactured for the transportation and distribution of electrical energy between 32A and 6300A.

Lighting Busbar System: It is produced to feed lighting circuits between 25A and 32A.

Trolley Busbar System: It is designed to provide energy to moving machines. The current collector car, which has coals that provide energy transfer from the busbar, is mechanically connected to the moving systems and moves with the system, ensuring uninterrupted energy transfer.

Busbar Prices

The basic components of the busbar system are copper, aluminum, and sheet metal. Busbar prices vary depending on free raw material market conditions. Therefore, to find out the current Busbar prices, you can access the correct information by contacting the ” Busbar manufacturer EAE Elektrik”, which is among the largest and most reliable manufacturers in Turkey and the world.

Leave a Reply